a) Written procedures for approval and rejection of materials The procedures need to detail: Receipt Identification Storage Handling Representative sampling Upon receipt Examination and/or testing

Sep 30, 2016 · Understanding container closure integrity systems, reviewing past observations, and following the regulations and guidance documents are excellent ways to establish a compliant container closure integrity assay. This article describes recent changes to the United States Pharmacopeia (USP) , guidance documents, regulatory observations, common container closure methods, and provides

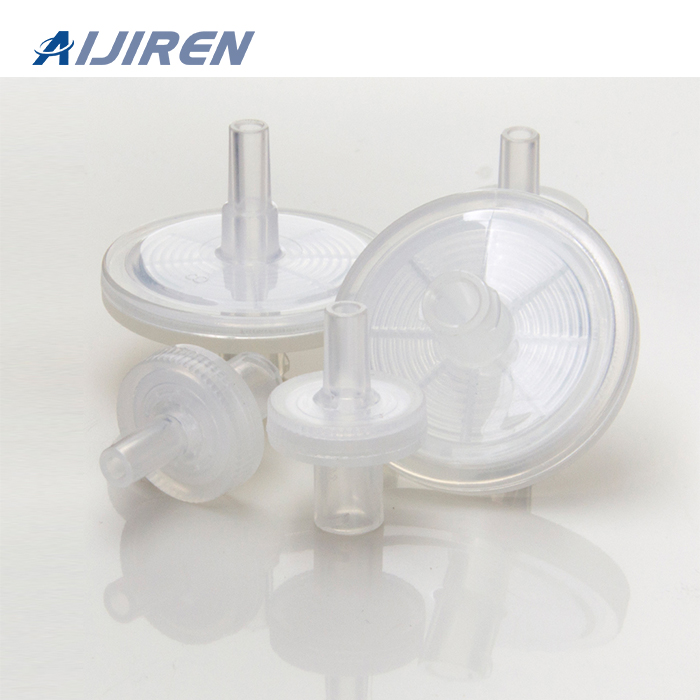

Aug 11, 2019 · Bolus injection: Filter prior to administration using a sterile, nonpyrogenic, low protein–binding syringe filter. 7. Continuous infusion: Either use a sterile, nonpyrogenic, low protein–binding syringe filter during preparation or administer with an in-line, sterile, nonpyrogenic, low protein–binding filter. 7.

Mar 14, 2022 · The global injectable drug-delivery device market, which includes conventional syringes, needle-free injectors, autoinjectors, pen injectors, and dual-chamber devices (powder and liquid), is expected to grow from $15.38 billion in 2020 to $17.13 billion in 2021 at a CAGR of 11.4% and $25.79 billion in 2025 (CAGR of 10.8% from 2021 to 2025). 2.

3. The manufacture of sterile pharmaceutical products using Blow-Fill-Seal-Technology, PDA, Technical Report No. 77, 2017 4. EU Guidelines to Good Manufacturing Practice, Annex 1, Manufacture of Sterile Medicinal Products, Brussels, 2008 5. Michael Spallek et al., Heat effects on sensitive formulations during blow-fill-seal processing, PDA

These guidelines have been prepared to assist pharmaceuti-cal manufacturers and pharmacists in the development and production of single unit and unit dose packages, the use of which has been shown to have substantial benefits. A single unit package is one that contains one discrete pharmaceutical dosage form, i.e., one tablet, one 2-mL vol-

73 Prefilled Syringe User Requirements for Biotechnology Applications 2015 43525 74 Reprocessing of Biopharmaceuticals 2016 43526 75 Consensus Method for Rating 0.1μm Mycoplasma Reduction Filters 2016 43528 76 Identification and Classification of Visible Nonconformities in Elastomeric Components and Aluminum Seals for Parenteral Packaging 2016

Jun 1, 2019 · 19. CSP HANDLING, STORAGE, PACKAGING, SHIPPING, AND TRANSPORT 19.1 Handling and Storing CSPs 19.2 Packaging of CSPs 19.3 Shipping and Transporting CSPs 20. DOCUMENTATION 21. COMPOUNDING ALLERGENIC EXTRACTS GLOSSARY APPENDIX 1. INTRODUCTION AND SCOPE This chapter describes the minimum standards to be followed when preparing compounded sterile

Nov 17, 2021 · Current guidance on analytical methods and particulate matter limits in injectable drug products are published in national and regional pharmacopeias. Requirements include being essentially free of visible particulates. Particulates, if present, can interact with the injectable drug product and change the chemical consistency.

Jun 15, 2020 · Guideline on Plastic Immediate Packaging Materials: Requirements for plastic immediate packaging materials (CPMP/QWP/4359.03, 2005) EMEA/CHMP/ QWP/49313: Guideline on the Pharmaceutical Quality of Inhalation and Nasal Products: The document includes products for administration of the drug substance to the lungs.

Considered for: Prefilled Syringe (PFS), Small and Large Volume Parenterals (SVP)/(LVP), and Ophthalmic/Blow Fill Seal (BFS) Disposable systems should also be considered in the absence of defined and specific regulatory guidance Consistent with the principles of QbD and good science

EU: Prefilled Syringe is a Medicinal Product Drug delivery system and container closure - in case of PFS: • Prefilled syringe is a single integral medicinal product • Inteded exclusively for use in the given combination • Non reusable To be considered: 1. General safety and performance requirements (GSPR) - EU MDR Annex 1 Chapter 1 2.

Guidelines on packaging for pharmaceutical products Introductory note 120 Glossary 121 1. Aspects of packaging 125 1.1 General considerations 125 1.2 Functions of packaging 127 1.2.1 Containment 127 1.2.2 Protection 127 1.3 Presentation and information 129 1.3.1 Labels 129 1.3.2 Repacking, relabelling and dispensing 130

package (containers–closures or packaging material for medical devices) and the transfer of the product into the container and its closure under at least ISO Class 5 (see . Table 1) conditions. Beyond-Use Date (BUD) (see . General Notices and Requirements . and . Pharmaceutical Compounding — Nonsterile Preparations

1 Scope. This International Standard specifies requirements and test methods for empty, sterile, single-use syringes, with or without needles, made of plastic materials and intended solely for the injection of insulin, with which the syringes are filled by the end user. This International Standard covers syringes intended for single-use only in