(USP) chapter 797, Pharmaceutical Compounding—Sterile Preparations.15 To help achieve that harmonization, these guidelines employ the definitions and terminology of USP chapter 797 rather than those of the previous guidelines. Many health care settings also use CSPs prepared by compounding pharmacies. Although these guidelines

ISMP Safe Practice Guidelines Adult IV Push Medications • Risks associated with drug storage, stock, standardization, and distribution • IV push drug dosages that need to be manipulated (e.g., vial-to-syringe or syringe- to-syringe transfer, dilution, use of a partial vial or ampule, more than one vial or ampule to prepare a dose)

Implementation of Single-Use Assemblies for Final Sterile Filling - PDAThis presentation discusses the benefits, challenges and best practices of using single-use systems for sterile filling operations in the pharmaceutical industry. It also provides case studies and examples of how to perform process simulation testing and filter integrity testing for single-use assemblies.

use a sterile 10-mL syringe and 18-gauge needle to exchange two 5-mL aliquots of medium from one container to the other in the pair. Then, inject a 5-mL aliquot from each container into a sterile 10-mL clear vial (three total), using a sterile 10-mL syringe and vented needle or pin. High Dissolve 3 g of non-sterile commercially available

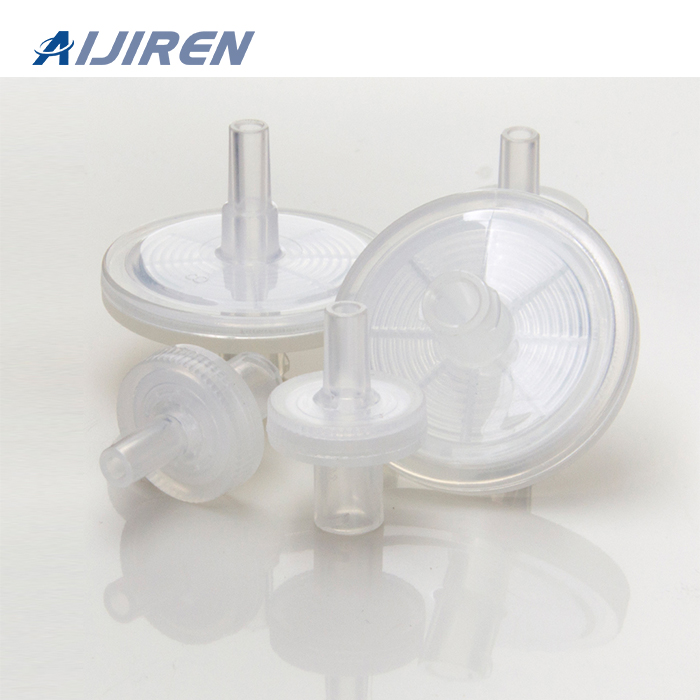

Feb 7, 2023 · A syringe filter (or wheel filter) is a single-use, membrane-based device used for the removal of particulate impurities from small (≤ 100 mL) liquid samples Selected based upon the desired end application, disposable syringe filters are commonly used in labs for fast and efficient filtering, material purification, or even sterilization.

testing is the syringe filter. These are available with a wide range of membranes, pore sizes, and filter sizes. Depending on the design, syringe filters may be compatible with automated filtration systems. The main disadvantage of syringe filters is that the filtration process is manual and needs to be done one at a time, which can be challenging

Browse All Hydrophobic PTFE Syringe Filters >>. PTFE Hydrophobic Filters Chemical Compatibility Chart >>. PTFE Hydrophilic Syringe Filters 0.2 or 0.45um . Resisting nearly all corrosive chemicals makes PTFE syringe filters an ideal choice. However, natural hydrophobic PTFE has it’s disadvantages not letting aqueous solutions

A syringe filter (or wheel filter) is a single-use, membrane-based device used for the removal of particulate impurities from small (≤ 100 mL) liquid samples ( Figure 1 ). Selected based upon the desired end application, disposable syringe filters are commonly used in labs for fast and efficient filtering, material purification, or even

syringe would require estimation of the volume (e.g., measuring 4.5 mL in a 5-mL syringe with no mark at the 4.5-mL level), the use of two sy-ringes of appropriate capacities (or two separate syringe “loads”) should be considered in order to provide a more accurate measurement. c. A fresh disposable needle and syringe should be

¥ÿŸ `ž{¸ çb õŸžìý ×—Ó»èËþåõUßÅô®úúúúôLÅ&‡á÷/ t( ôïV[[t’É¿ ¿uÐY ž¼ ݵÿ[Ý’/ AK íðÖ‚ •¶æy Q»- à 3 ,PJ[’&Øn ´T‚ ò rs¶µ¹§;Êòéƒ 7?

Mar 11, 2021 · A filter needle (e.g., 19-gauge × 1½-in., 5-μm) is attached to a syringe and the formulation is drawn aseptically into the syringe from the vial. The plunger rod is pulled back sufficiently to ensure the formulation is in the syringe completely before removing the filter needle and replacing it with a needle which will be used for the IVT

It may be necessary to use successive small injections and withdrawals to exchange the air in the syringe with the solution in the vial. Fill the syringe to a slight excess of the drug solution. Remove all air bubbles from the syringe by tapping the syringe. Then fill the syringe to the correct volume once air bubbles have been removed.

85. “The integrity of the sterilised filter should be verified before use and should be confirmed immediately after use by an appropriate method such as a bubble point, diffusive flow or pressure hold test. The integrity of critical gas and air vent filters should be confirmed after use. The integrity of other filters should be confirmed at

Aqueous flow rates for various filter sizes to achieve complete wetting Filter Style Associated Typical Wetting Flow Rate Wetting Flow Rate Description Part Number Prefix Filtration Area for 0.2 µm filters for 0.1 µm filters Mini Kleenpak™ syringe filter capsules KM2 2.8 cm2 3 mL/min 1 mL/min

filled syringe as designed for the intended use (environmental conditions etc.) Procedure. Luer connector leakage method ISO 11040 – 4; (TM = Annex G) Connectivity following ISO 80369 -1. Interpretation of Results. Compare leakage results with pre- defined specification ( as for the intended use)