100% integrity tested, nonpyrogenic and noncytotoxic, manufactured in accordance with ISO 9001 standards. Order Info. Pore size and membrane type is printed on every syringe filter. Sterile filters are individually blister-wrapped in cases of 50, nonsterile in cases of 50. Compliance. Manufactured to ISO 9002 and GMP standards, and 100%

Lower hold-up volume - due to an improved flow channel design and reduced spacing between the supports within the housing, for better handling of small sample volumes or costly samples Increased operating pressure - up to 130 psi due to the over-mold that prevents sample leaking at the seam and keeps the filter unit from bursting in half

Lower hold-up volume - due to an improved flow channel design and reduced spacing between the supports within the housing, for better handling of small sample volumes or costly samples Increased operating pressure - up to 130 psi due to the over-mold that prevents sample leaking at the seam and keeps the filter unit from bursting in half

Feb 17, 2020 · Open the syringe filter package so that you can later pick the filter up easily, especially for individually packed sterile syringe filters. a. For sample volume < 10 mL. Draw a small amount of air (about 1 mL) into the syringe before loading the sample solution. The air is used to purge the filter to minimize hold up volume.

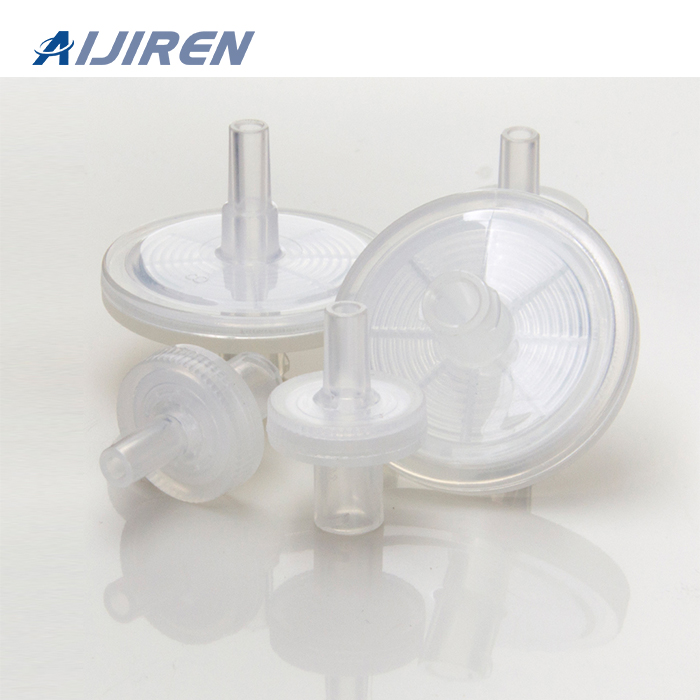

13mm and 25mm Syringe Filters (low hold–up volume) designed for robotic devices (25mm R). ... Engineered and manufactured in compliance with ISO 9001:2008 ...

Corning™ RC Syringe Filters 0975423 manufactured in accordance with ISO 9001 standards. ... Hold up Volume (After Air Purge)

Corning™ RC Syringe Filters 10670502 manufactured in accordance with ISO 9001 standards. ... Syringe Filter: Diameter (Metric) 15 mm: Hold up Volume (After Air ...

Product Description. Mini Syringe Filters are 0.22 um sterile filters for filter sterilization of 100 uL to 1 mL of aqueous solution with only 10 uL hold-up volume. For convenience, we offer these filters in a pack of 5 or in a kit for filtering 5 samples.

All CHROMAFIL syringe filters are autoclavable (121 °C and 1.1 bar for 30 min). CHROMAFIL syringe filters possess distinct benefits in use: Different membrane types to meet multiple filtration needs; Low content of extractable compounds; Fast flow geometry for easy filtration; Low hold-up volume for maximum filtrate recovery; HPLC certified

These housings hold one single-open ended(SOE) AB sanitary style code-7 filter cartridge. Benefits of this housing are: Low Hold-Up Volume– maximizes product recovery. Easy-draining features. Including downward sloping internal contour and low-point drain– allow easy removal of CIP solution or product.

Another aspect of choosing the right filter size is the hold-up volume. This is the volume of liquid remaining in the filter after use. A filter with a low hold-up volume is recommended for use with expensive fluids or those with limited availability. Here are examples of the hold-up volumes of Pall’s non-sterile syringe filter range:

• Low extractables • Consistent particle retention • Also available in OEM, custom or Private Label configurations Membrane Solutions® Syringe Filter have the following features: < 1 mL 1 – 10 mL 10 – 100 mL >100mL >1L 4 13, 17 25, 30 30,33 50 Typical Process Volume Suitable Syringe Filter Diameter (mm)

May 26, 2014 · In the medium to long term, we should see a crosspollination of process im-. 60 EXPRESS PHARMA May 16-31, 2014. In terms of the industry’s economic strength, the findings show that the sector is

Polypropylene housing. Female Luer-Lok inlet standard male slip Luer outlet. \<100uL hold-up volume. 1000/pk. 8. $1,907.74 4504. Acrodisc Syringe Filters With Supor Membrane Non-sterile Bulk Packaging. 0.8/0.2 um 25 mm. Effective Filtration Area: 2.8 cm2. Typical Hold-up Volume (with air purge):\< 70 uL.

• Lower hold-up volume - due to an improved flow channel design and reduced spacing between the supports within the housing, for better handling of small sample volumes or costly samples • Increased operating pressure - up to 130 psi due to the over-mold that prevents sample leaking at the seam and keeps the filter unit from bursting in half