Operation conditions: Typical Operation Pressure: 30-120 psi (2.1-8.3 bar) Maximum Applied Pressure: 140 psi (9.7bar) Maximum Chlorine Concentration: 200PPM @ pH>10.5 Maximum Operating Temperature: 131 F (55℃) Operating pH Range: 2.0 - 10.0. Benefits: 1. We use high quality membrane sheet to promise products performance. 2. We offer OEM

Operating Pressure: Ranges between 0.5 Bar and 3 Bar depending on raw water quality and temperature Maximum Operating Trans Membrane Pressure: 2.1 Bar Max Operating Temp: 40°C Operating pH Range: 5-10 Raw Water Quality: Up to 100 mg/l TSS (300 NTU). A raw water analysis should be provided to establish the extent of pre-treatment necessary

Maximum Operating Conditions Recommended Feed Flow Rate: 4–8 L/m2/min Maximum Inlet Pressure: 100 psi Forward Transmembrane Pressure: 80 psi (5.5 bar) at 4–40 °C, 200 hours continuous (4 hours continuous, 88 cm2 format only) 40 psi (2.7 bar) at 4–50 °C, 50 hours continuous Reverse Transmembrane Pressure: 30 psi (2.1 bar) at 25 °C, 3 min

Since pressure-driven membrane processes such as RO cannot treat concentrated brines because of their high osmotic pressures, thermal desalination technologies must be used [13,14].

Maximum operating pressure [bar] Maximum operating temperature Height Width [°C] Single 0006 Etched, passivated and electro-polished, Ra < 0.8 inside and outside 267 120 0.60 1.50 16 -25/+150 0018 319 120 0.80 1.70 0032 379 162 1.80 2.10 0072 506 162 3.20 2.90 0144 789 206 5.40 4.50 0192 1043 206 7.40 5.70 Multiple 0432 Etched, passivated and

(1.9 bar / 27.6 psi) The operating pressure in your home should be tested over a 24 hour period to attain the maximum pressure. If it is above 0.63 MPa (6.3 bar / 91.4 psi), then a pressure regulator is necessary, and will be required. Dimensions (length х height х width): 371 х 420 х 190 mm Maximum flow rate membrane cartridge (water

• High-quality snap-action switch • Factory preset • Available in a wide range of configurations • Economical • Pneumatic and hydraulic applications • NEMA 4, 13 Operating Specifications Set Point Range 2 — 120 PSI (.14 — 8.3 Bar) Set Point Tolerance ±1 PSI or 5% (.07 Bar) Maximum Operating Pressure 250 PSI (17 Bar)

Compressed air inlet pressure (min-max): 4-14 bar(e), 58-203 psig Compressed air inlet temperature (min-max): 1-66 °C, 32-150°F Ambient air temperature (min-max): 1-66°C, 32-150°F Other pressure, pressure dew point suppressions and inlet dew points: • For pressures other than the ones mentioned above, correction

n Feed pressure should be increased gradually over a 30 –60 second time frame. n Cross –flow velocity at set operating point should be achieved gradually over 15 –20 seconds. n Permeate obtained from first hour of operation should be discarded. n Maximum pressure drop across an entire pressure vessel (housing) is 30 psi / 2.1 bar.

Maximum Operating Pressure: 600 psi (41 bar) pH Range, Continuous Operation*: 2 –11 Product Specifications Test Parameters: 550 TDS Filtered (5 Micron), De-Chlorinated, Municipal Feed Water, 77 Degrees F, 15% Permeate Recovery, 6.5 - 7.0 pH Range, at the Specified Operating Pressure. Data Taken After 30 Minutes of Operation.

Maximum Operating Pressure & Temperature, Liquids Maximum Operating Pressure & Temperature, Gas 75 psig @ 32°F to 100°F 50 psig @ 32°F to 100°F (5,2 bar @ 0°C to 38°C) (3,4 bar @ 0°C to 38°C) 45 psig @ 140°F 30 psig @ 140°F (3,1 bar @ 60°C) (2,1 bar @ 60°C) UltraCap® H.D. Model

Test Parameters: 35,000 TDS Filtered (5–Micron), Dechlorinated, Municipal Feedwater, 45 psi / 3.1 bar Feed Pressure, 850 psi / 58.61 bar Operating Pressure, 77°F / 25°C, Recovery as stated, 7.0 pH. Data taken after 60 minutes of operation. A. applications which do not meet or exceed minimum and maximum operating limits for such conditions. B.

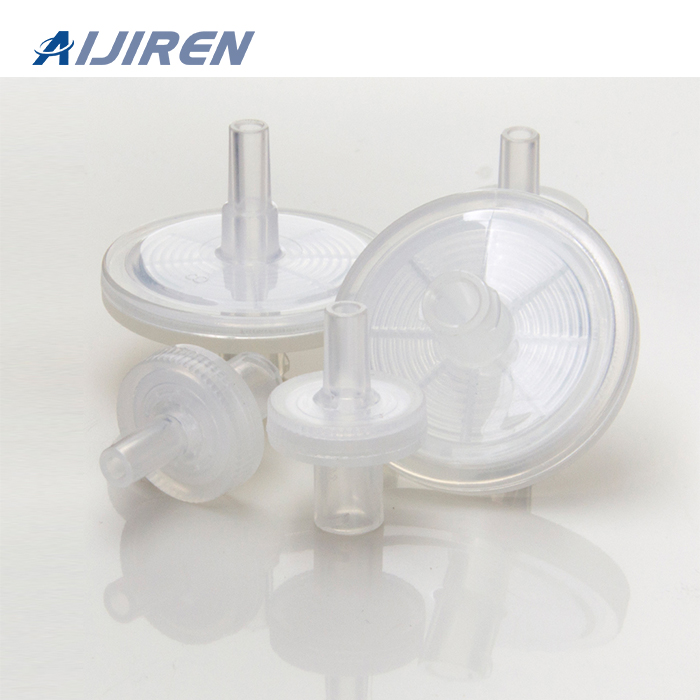

Flow rate: 78mL/min at 2.1 bar. Pall Filter 4907. Acrodisc Sterile Syringe Filter with 0.2um Fluorodyne II Membrane Membrane is hydrophilic polyvinylidene fluoride. For scale up. Polypropylene. Bacterial retention tested. Integrity testable. Filtration area: 2.8cm2. Female Luer-Lok inlet/male slip luer outlet. Flow rate: 130mL/min at 2.1 bar.

Avoid any abrupt pressure operating state is recommended as follows: • Feed pressure should be increased gradually over a 30-60 second time frame. • • • Maximum pressure drop across an entire pressure vessel (housing) is 30 psi / 2.1 bar. • Avoid static permeate-side backpressure at all times.

Operating Limits Membrane type Maximum operating temperaturea Maximum operating pressure Maximum pressure drop Maximum feed flow rate, gpm (m3/h) pH range, continuous operationa pH range, short-term cleaningb Maximum Feed Silt Density Index Free chlorine concentrationc Polyamide Thin-Film Composite 113°F (45°C) 600 psig (41 bar) 15 psig (1.0 bar)