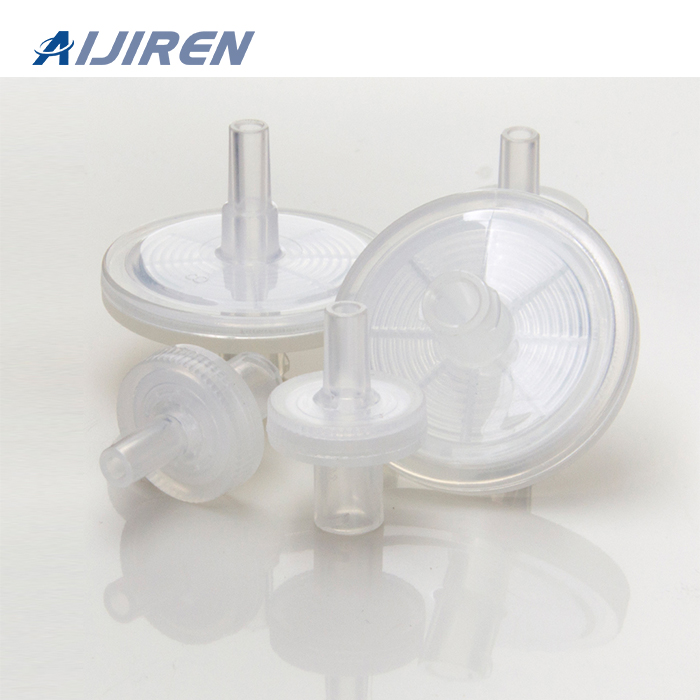

Samples were pre-dissolved in the mobile phase (DMSO/LiBr, 10mM) and filtered through a syringe filter (GHP Acrodisc, d=13 mm, 0.2-µm GHP membrane) prior to analysis. Isocratic separation was performed with a flow rate of 0.5 mL/min. Data analysis was performed using Cirrus GPC software version 3.2.

High performance 2-way pilot operated Best performances for minimum and maximum operating pressure diff erential ... 0.2 0.30.4 0.5 0.6 0.8 1.0 1.5 bar 2 1/2" 0.1 ...

Pressure Ratings: Maximum Allowable Operating Pressure (MAOP): 200 psi (13.8 bar) Design Safety Factor: 2:1 Rated Fatigue Pressure: 150 psi (10.3 bar) Element Burst Rating: 70 psid (4.8 bar) Filter Materials: Head, Cover, Flanges: die cast aluminum Bowl: steel Operating Temperatures: Nitrile: -40°F to 225°F (-40°C to 107°C)

Acrodisc, Syringe Filter, GHP, 25 mm, 0.2 µm, Aqueous, 50/pkg Acrodisc, Syringe Filter, GHP, 25 mm, 0.2 µm, Aqueous, 50/pkg, Polypropylene, 100 mL Sample Volume, 100 µL Hold up Volume Acrodisc Syringe Filter with Glass PreFilter GHP 2 – govsci.com Acrodisc, Syringe Filter with Glass PreFilter, GHP, 25 mm, 0.45 µm, Aqueous, 50/pk; Price: $241.40 / PK Average lead time, Pall Acrodisc

30 Acrodisc PSF (25 mm Syringe Filter) Product Specifications Typical Hold-Up Maximum Maximum Typical Part Pore Volume Operating Operating Water Number Description Size (w/air purge) Temperature Pressure Flow Rate AP-4305 GxF/GHP 0.2 µm < 200 µL 55 °C (131 °F) at 2.1 bar 4.1 bar (410 kPa, 60 psi) 175 mL/min at 2.1 bar AP-4307 (210 kPa, 30

Maximum Discharge Pressure* GPH L/H PSIG BAR PSIG BAR PSIG BAR PSIG BAR PSIG BAR PSIG BAR 8K 49 2.1 7 3440 237 3675 250 — — — — — — — — 8J 70 3.0 11 1625 112 3215 222 3675 250 — — — — — — 7⁄ 16″ 8H 95 4.0 15 1110 77 2440 168 3675 250 — — — — — —

Acrodisc® Units with Mustang® E Membrane - Pall Corporation Filter Media: Mustang E membrane; Housing: Polypropylene; Pore Size. 0.2 μm; Inlet/Outlet Connections. Female luer lock inlet, male slip luer outlet; Membrane Bed Volume. 0.12 mL; Maximum Operating Temperature and Pressure. 2.1 bar (210 kPa, 30 psi) at 60 °C (140 °F) or 5.5 bar

Maximum Operating Temperature* – 60 ºC (140 ºF) at 2.1 bar 60 ºC (140 ºF) at 1.0 bar (210 kPa, 30 psi) (100 kPa, 15 psi) Maximum Operating Pressure* – 5.4 bar (540 kPa, 80 psi) 4.1 bar (410 kPa, 60 psi)

Gas filtration & Purification - Pall Corporation. Operating Conditions. Maximum Operating Pressure: 2200 psig / 152 bar; Maximum operating temperature: 100 °C / 212 °F (INP, SIP, FCP, SF6P) 40 °C / 104 °F (GEH4P, OXP, CLXP, HCLP, HBRP, CDAP) EU Pressure Equipment Directive: Assemblies have been evaluated and are CE marked per the European Union's Pressure Equipment Directive 2014/68/EU.

Maximum Operating Temperature 60 °C (140 °F) at 2.1 bar (210 kPa, 30 psi) Maximum Operating Pressure 5.4 bar (540 kPa, 80 psi) at ambient temperature Typical Water Flow Rate mL/min at 2.1 bar (210 kPa, 30 psi) PN 4905: 130 PN 4906: 78 PN 4907: 130 PN 4908: 77 Recommended Integrity Test Minimum Bubble Point – Water PN 4905: 3.5 bar (350 kPa

ghp acrodisc maximum operating pressure 2.1 bar Acrodisc PSF Syringe Filters – Medigene Sdn. Bhd. high operating pressures to avoid filter burst AP-4307 2.1 bar at 21-24 °C (70-75 °F) at 2.1 bar

(1) Calculation of the minimum pilot pressure at a ∆P of max. 10 bar with allowable backpressure (backpressure not recommended with liquids as waterhammer may occur). - 32 and 50 mm operators, 4 bar minimum pilot pressure version: add 2 bar to the minimum pilot pressure of chart V or X [see page: 7 (www.asco.com)]

Maximum Operating Pressure: 3 bar (44 psi) at 40 °C: 3 bar (44 psi) at 40 °C: 3.5 bar (50 psi) at 25 ºC 1.0 bar (14.3 psi) at 60 ºC: Maximum Differential Pressure: 1.5 bar (22 psi) 1.5 bar (22 psi) 2.4 bar (35 psi) at 25 ºC: Maximum Operating Temperature: 40 °C: 40 °C: 60 °C: Sterilization Autoclaving: 1 x 30 minute at 125 °C: 1 x 60

Acrodisc Syringe Filters with GHP Membrane 55 C (131 F) at 2.1 bar (210 kPa, 30 psi) Maximum Operating Pressure 13 mm: 6.3 bar ... Performance GH Polypro (GHP) ...

Laboratory Acrodisc ® filters are recommended. Solvents containing suspended particulate materials will generally clog the outside surface of the inlet distribution frit of the column. This will result in higher operating pressure and poor performance. Degas all solvents thoroughly before use to prevent bubble formation in the pump and detector.