parameters such as line pressure fluctuations and flux (flow rate per filter area). As such, many filter vendors do not assign claims for microbial removal or retention to sheet-based products. Membrane filters in liquid or compressed air/gas applications are best used together with effective

MS ® high flow filtration systems enable high-flow filtration in high-pressure vessels to provide ideal protection of reverse osmosis membranes. MS ® 600 FlowPure-HF cartridge filter is designed in innovative technology to achieve flow rate up to 450gpm per 40inch element. It can provide absolute efficiency for consistent product quality and multi layer pleated construction with optimized surface.

Filter Flow Rate Calculation Metric All filter media has optimum flow rates where that media will perform the best and provide the best water filtration performance. This flow rate can be measured in the amount of gallons per minute that can flow through one square foot of filter media square area. Step 1 – Enter Continue reading Filter System Flow Rate Calculator

Aug 29, 2017 · Concerning air flow rate, the quality factor and filtration efficiency of the electrospun membranes at higher face velocity are much more stable than for commercial membranes. The results suggest that the structure of electrospun membranes is the best for air filtration in terms of filtration stability at high air flow rate.

Includes two RO membranes (HL22045), one KDF/Carbon material filter (HL22043), and all required fittings. The Pre-Evolution is recommended if more than 150 gallons per week is produced (see Related Items tab). From the Manufacturer. High flow reverse osmosis system. 1,000-Gallon per day. High Flow Reverse Osmosis System. Thankless RO System.

Flow Rate: 0.75 GPM: Filter Housings: 1: Dirt Holding Capacity: 1.25 lbs: Water Holding Capacity: 0.25 gallon: Housing Oil Capacity: 5 quarts: Min./Max. Pressure at Flow Control Valve: 200 - 3,000/5,000 psi *Every industrial application and environment is different. Units are sized for a 15% turn of a hydraulic reservoir every hour.

Volume (L) Process time (h) The permeate volumetric flow rate is calculated from the formula: Volumetric flow rate (L/h) = Flux (L/m2/h) * Filter area (m2) The volume for the first concentration step is calculated by using the formula: Volume (L) = Starting volume (L)- (Starting volume (L)/Concentration factor)) The volume for the diafiltration

Pall Ultrafiltration Membrane Disc Filters also for bench or pilot separations prior to scale-up. Pall Ultrafiltration Membrane Disc Filters available in a broad range of membrane diameters to fit various sizes. Omega membrane discs provide unmatched high flow rates and recoveries, and can be washed and reused as many as 20 times.

Filtrate: Filtrate is the water that has passed through the membrane. , i.e., the water passing through the membrane, per unit area of membrane: Equation 1. Where: J = flux, L/hr/m 2 (gal/d/ft 2) or Lmh (gfd) Qp = filtrate flow rate through membrane, L/hr (gal/d) Am = surface area of membrane, m 2 (ft 2) Note that the flux unit of L/hr/m 2 is

Flow Rate: Defined as the time required for the flow stream to pass through the filter, flow rate may be measured for air or liquid. Flow rate generally decreases with smaller pore size, but altering membrane material, thickness, porosity, and pore architecture can lead to differences in flow rate.

In this situation, very high protein concentrations at the membrane surface and high membrane fouling may occur, especially during the process start-up. You must control the filtrate flow to reduce the filtrate rate and control the TMP at the low values required for robust tangential flow filtration (TFF) operations.

High Flow Rate Membrane Optimized for Biological, Pharmaceutical, and Sterilizing Filtration Requirements. 47 mm, plain high flow rate membrane disc filter (100/pkg), Supor 200 Membrane Disc Filters - 47 mm, plain (100/pkg) Additional Information: Item Code: 60301; Delivery Time: 4-8 days; Packaging Details: 100/pkg

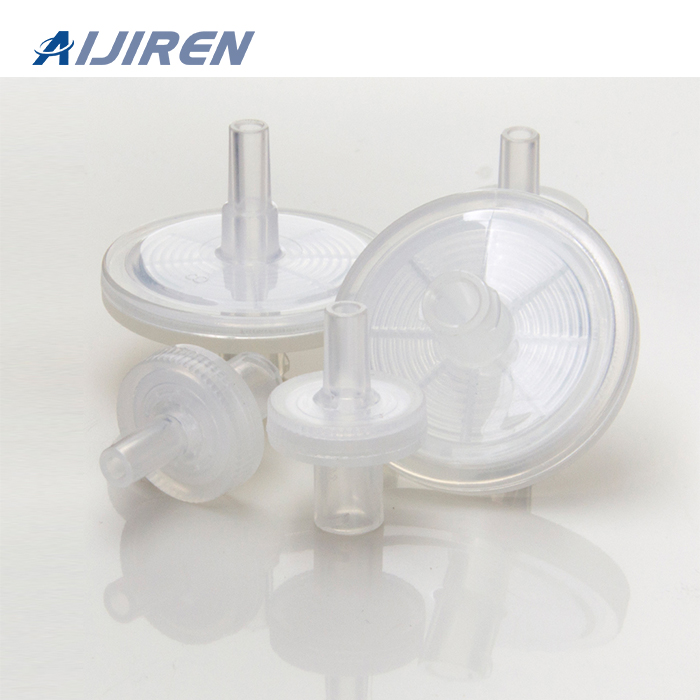

In terms of particle retention, filters fall into two categories: surface filters and depth filters. Surface filters, generally referred to as membranes, trap particles exclusively on the top surface. These filters are well suited to samples with low particulate content. However, high particulate content tends to rapidly clog the filter surface.

One ml of the solution was transferred into a 10 ml volumetric flask, added with 0.01 N HCl to the mark, and then filtered through a 0.45 μm GHP syringe membrane filter (concentration 27.78 ppm). The standard concentration represents the concentration of captopril in 900 ml of 0.01 N HCl if 100% of the captopril in the tablet is completely

Permeate flow rate = 325 m 3 /d. Feed pressure = 6000 kPa. Pressure of brine reject = 5900 kPa. Permeate pressure =101 kPa. Salt concentration in membrane = 1.76 C f. –. The salt rejection definition is used to calculate the product salinity, where. SR = 1 − X p / X f 0 .99 = 1 − Xp / 34000. which gives X p = 340 ppm.