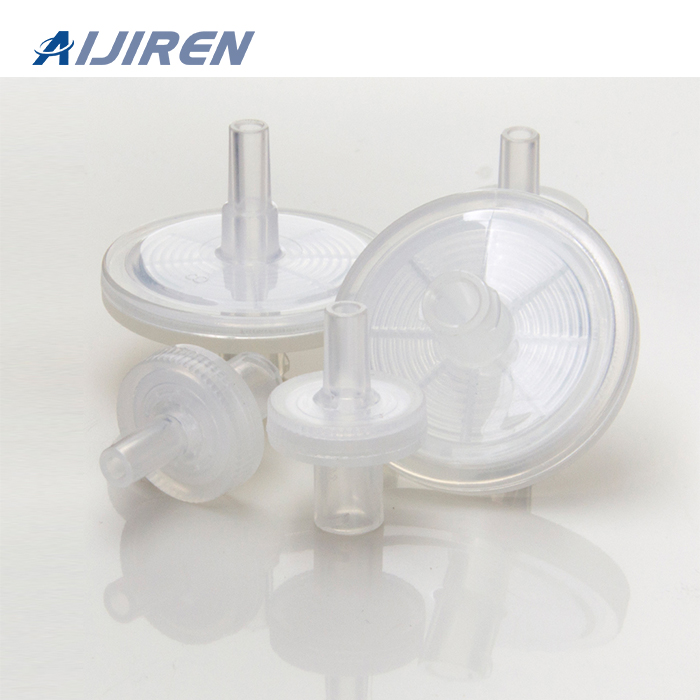

Effective filtration area: 13 mm 0.8 cm2. 25 mm 4.6 cm2. 40 mm 10.5 cm2. 50 mm 15.9 cm2. Connections: enhanced female Luer-Lok inlet, male Luer slip outlet.

Effective Filtration Area 0.9 cm2 Dimensions Overall Length: 32 mm (1.25 in.) Diameter: 16 mm (0.6 in.) Inlet/Outlet Connections Standard female Luer-Lok♦ fitting, male slip luer outlet Maximum Operating Temperature Limited by filter type Maximum Operating Pressure 6.9 bar (690 kPa, 100 psi) Sterilization

Effective Filtration Area (cm2): 1.65 Pore Size (µm): 0.22 µm Holdup Volume (µl): Sample Volume (mL Inlet Connection: Female luer lock Outlet Connection: Male luer slip Maximum Operating Temperature: 50 °C Maximum Operating Pressure: 6 bar Typical Applications High particulate samples

Effective Filtration Area. 4 mm: 0.2 cm 2; 13 mm: 1.0 cm 2; 25 mm: 2.8 cm 2; 25 mm PSF: 3.9 cm 2; Sample Volume. 13 mm: < 10 mL; 25 mm PSF: < 150 mL; Inlet/Outlet Connections. 13 mm: Female luer lok inlet, minispike outlet; 25 mm PSF: Female luer lok inlet, male slip luer outlet; Typical Hold-up Volume(with air purge) 13 mm: < 14 µL; 25 mm PSF

3) Add the pressure drop for the bag filter. Depth Nominal (inches) 6 12 Diameter (inches) 3.9 3.9 Surface Area (sq. ft.) 0.5 1.0 Volume (cu. in.) 65 130 Bag Size No. 3 4 For flow rates to 50 gpm* Pipe 2.0 Shown in Aluminum * Based on housing only. Fluid viscosity, bag filter used, and expected dirt loading should be considered when sizing a

Pall Filter Syrng 0.2UM Ghp PK1000 AP-4566 ON SALE . Pall Laboratory Filters, Syringe filters. +1-800-504-7309 Contact Check Order Status. About Us Knowledge Center

Filtration Area for Easy Operation and Fast Liquid Flow Economical for small-volume (10 to 100 mL) filtration. Accepts 25 mm filter discs. Luer inlet and outlet fittings provide easy connections. Delrin (acetal resin) construction provides broad chemical compatibility and material

Diameters : 32mm. Effective Filtration Area : 4.4 cm2. Length, Inlet to outlet : 26 mm. Housing material : Polypropylene (PP) Inlet Fittings : Female Luer-Lok. Outlet Fittings : Male Luer slip. Maximum Process Volume : 200 mL. Hold-up Volume (after air purge) : ≤ 80 μL. Maximum Operating Pressure : 10 bar (145 psi)

Filter media Polypropylene Effective filter area 3.9 cm 2 / 0.6 in 2 Operating Conditions 2 Maximum allowable pressure 2.1 barg / 30 psig @ 20°C / 68°F Materials of Construction Housing Polypropylene with white colorant Filter media Polypropylene or 300 series stainless steel Effective filter area 7.5 cm 2 / 1.16 in 2 Operating Conditions 2

.pall.com 3 Filter Holders Product Materials of Construction Inlet/Outlet Connections 13 mm Plastic Swinney Filter Holder Inlet/Outlet Housing and Support Screen: Celcon© (acetal copolymer) Female threaded luer inlet, male slip luer outlet Seal Washer: PTFE 25 mm In-line Filter Holder, Delrin© Plastic

Large Filtration Area for Easy Operation and Fast Liquid Flow Economical for small-volume (10 to 100 mL) filtration. Accepts 25 mm filter discs. Luer inlet and outlet fittings provide easy connections. Delrin (acetal resin) construction provides broad chemical compatibility and

Female Luer-Lok inlet standard male slip Luer outlet. \<100uL hold-up volume. 1000/pk. Pall Filter 4504 Acrodisc Syringe Filters With Supor Membrane Non-sterile Bulk Packaging. 0.8/0.2 um 25 mm. Effective Filtration Area: 2.8 cm2.

Nominal Effective Filter Area (EFA) 2.8 cm 2 (0.43 in.2) Connection Female Luer-lok inlet, male slip Luer outlet Shipping Format Pre-sterilized using gamma irradiation 350 ˚!#*˛() ’˛( ˆ&. 1000 800 600 400 200 0 0 10 20 30 40 Flow rate (mL/min), water at 20 °C For liquids other than water, multiply differential pressure by fluid viscosity

1. Attach pipework with the male Luer-Lok to the downstream side of the pressure vessel. 2. Connect the inlet of the capsule to the 3-way Luer-Lok stopcock. 3. Connect the stopcock to the pressure vessel via the male Luer-Lok. 4. Ensure that the unconnected female Luer port is shut off by the stopcock. 5.

1. Connect an arm of each female luer tee to both male luer retentate ports of the module. 2. Connect to the two remaining luer tee arms, a male luer cap and a male luer check valve. 3. Connect a second male luer cap to the female end of the check valve. 4. Connect luer syringes to the two open stems of the luer tees. One syringe contains the