Iso9001 ghp membrane filter maximum operating pressure 2.1 bar Acrodisc® Syringe Filters for Analytical Sample Preparation - Pall Acrodisc syringe filter housings will not rupture at their rated operating pressures.

3.9 cm² Filter Media Glass Fiber / GH Polypro membrane (GHP, hydrophilic polypropylene) Hold-Up Volume . 200 µL Housing Material Polypropylene Maximum Operating Pressure (bar) 4.1 bar Maximum Operating Temperature (Metric) 55 °C Typical Flow Rate 175 mL/min at 2.1 bar (210 kPa, 30 psi) Overview Description Type Use

low protein binding membrane ghp syringe filter maximum . low protein binding membrane ghp syringe filter maximum operating pressure 2.1 bar Supor® EKV Membrane Filters – Membrane Filters – Pall Maximum Operating Temperature * 60 ºC (140 ºF) at 2.1 bar (210 kPa, 30 psi) Maximum Operating Pressure* 5.4 bar (540 kPa, 80 psi) a

Maximum Operating Temperature * 60 ºC (140 ºF) at 2.1 bar (210 kPa, 30 psi) Maximum Operating Pressure* 5.4 bar (540 kPa, 80 psi) at ambient temperature: Recommended Integrity Test Minimum Bubble Point (Water) > 3.32 bar (332 kPa, 48 psi) Bacterial Retention: Lot samples retain a minimum of 10 7 cfu/cm 2 of B. diminuta per modified ASTM F838

Membrane: PES Supports: Polypropylene apsule ody: Polypropylene Operating Conditions Max. differential pressure: 30 psid (2 bar) Maximum Operating Pressure Liquid: 60 psig @ 77° F (4 ar @ 25° ) Maximum Operating Pressure Gas: 30 psig @ 77° F (2 ar @ 25° ) Maximum Operating Temperature: 60° Effective Filtration Area

The solid curve is a truly exponential pressure decay For the gas bubble, the important parameters are period of oscillation and maximum bubble U 39 TIME - * Fig 1 Pressure Waves and Bubble Phenomena of Underwater Explosions. The Upper Part Shows a Pressure-Time Plot, the Lower, the Position and Size of the Bubble for Specific Moments which Correspond to the Curve Above as Indicated by the

Sep 3, 2013 Typical materials used in modern filters include GHP was set at 0.3 mL/min in order to work within the pump operating pressure range. Get Price Acrodisc® syringe filters GHP membrane, diam. 25 mm, pore size

A common unit of pressure is the atmosphere (atm), i.e. the pressure exerted by the atmosphere at sea level (1 atm = 1.013 × 105 Pa). Another quantity, that is indispensable in describing fluids, is the density ρ. For a fluid of mass m occupying volume V, m ρ = (10.3) V The dimensions of density are [ML –3]. Its SI unit is kg m–3. It is a positive scalar quantity. A liquid is largely

Acrodisc PSF syringe filters are Zymark* and SOTAX* Automation Certified to ensure smooth operation and worry-free performance 24 hours a day in automated workstations. Avoid the expense and inconvenience of keeping a variety of filters on hand. Versatile filter for aqueous and aggressive organic solvent-based solutions.

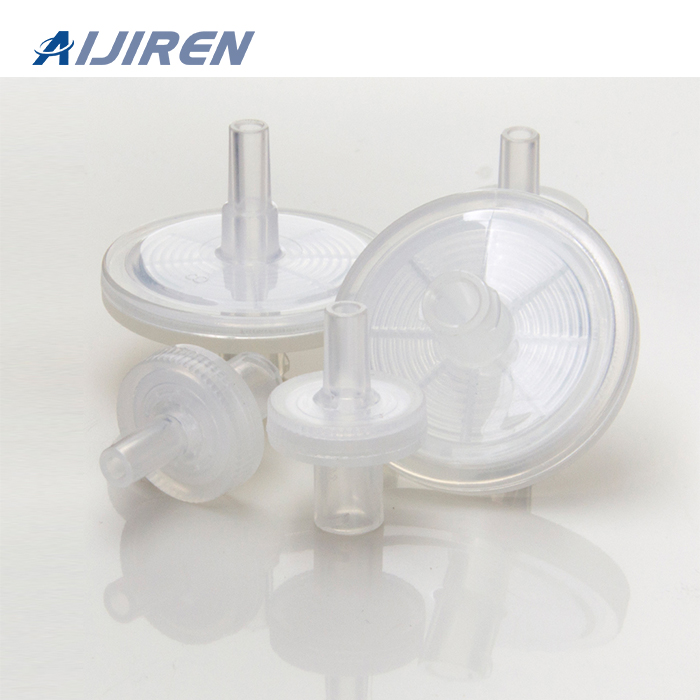

Home » News » GHP Filter » Professional ghp syringe filter maximum operating pressure 2.1 bar Professional ghp syringe filter maximum operating pressure 2.1 bar Determination of Table 3 Plus Compounds by LC/MS/MS 50:50 methanol:water, then vortexed and filtered with a 0.2 um GHP syringe filter.

25mm ghp filters maximum operating pressure 2.1 bar HPLC and Chromatography Sample Prep – VWR Acrodisc PSF GxF syringe filters with glass/GHP membrane Maximum Operating Pressure. 13 mm: 6.3 bar 2.1 bar (210 kPa, 30 psi) at 55 ºC.

Maximum Operating Pressure. 13 mm: 6.3 bar Get Price. Latest Update of analytical testing vials and hplc autosampler vials . Syringe Filters – GHP Acrodisc® and GHP Acrosdisc® GF, Pall General-purpose syringe ty low protein binding membrane ghp me ...

Acrodisc® Syringe Filter with wwPTFE membrane & wwPTFE Membrane Disc Filters, Pall. Avoid the expense and inconvenience of keeping a variety of filters on hand. Versatile filter for aqueous and aggressive organic solvent-based solutions. AutoPack™ packaging is easy to use and the Automation Preferred™ certification assures you of smooth

Visit One News Page for Blood Donation news and videos from around the world, aggregated from leading sources including newswires, newspapers and broadcast media.

3 Now slowly draw at the syringe, as if filling the syringe, until the pressure (as displayed on the digital barometer) drops to approximately 350 mbar below ambient pressure.Then close the line to the syringe at the 3-way stopcock to syringe (circled in picture below). 4 Let the reading on the digital barometer stabilize for a moment and then perform the leakage check: for 30 seconds the